Enhance Student Learning with Interactive AR Visualizations

Interactive AR Visualizations

Objective

Enable students to visualize the models they designed in 3D, in the real environment

Allow students to share and collaborate on designs as 3D holograms

Reduce the number of iterations of a prototype that need to be produced as physical models by allowing students to see the models as holograms in the real environment prior to prototype fabrication

Overview

Dr. Biruk Gebre, Department of Mechanical Engineering, and the XR Lab team at Stevens Institute of Technology used the HyperSkill platform and Microsoft Hololens 2 in Dr Gebre’s Introduction to Additive Manufacturing and Senior Design classes.

Key Features

- Augmented Reality

- Multiplayer

- Collaborative Design Reviews

- Design Verification in XR

- Visualization of 3D models

Solution

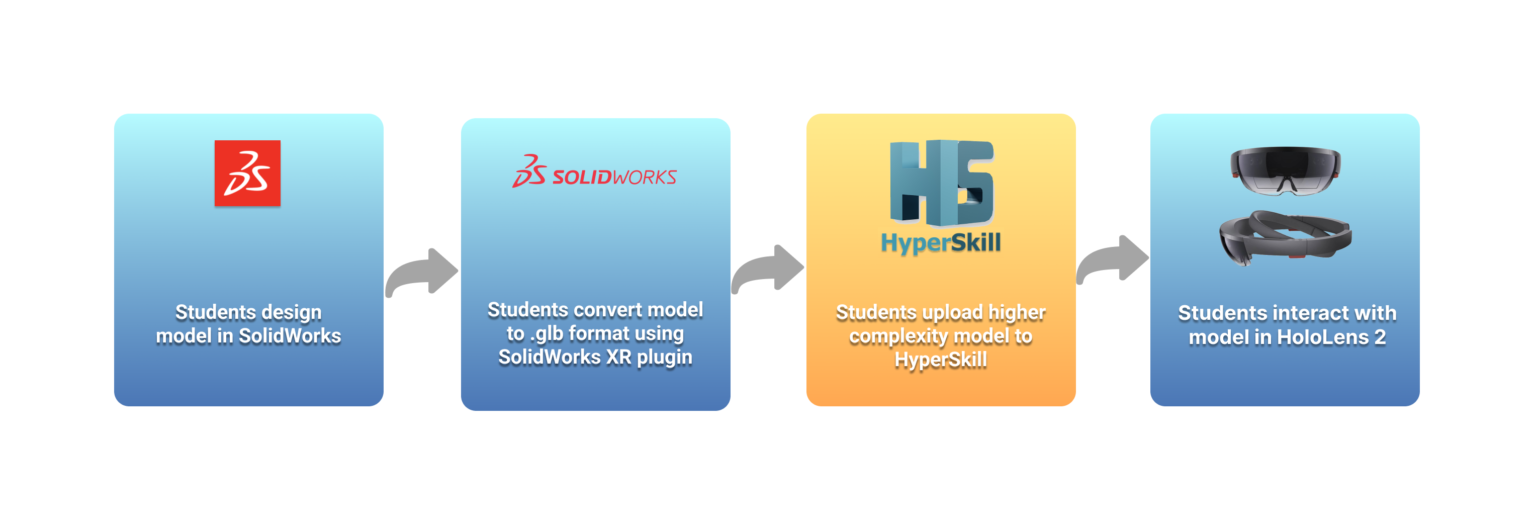

Mechanical engineering students used the HyperSkill platform to import 3D models designed in SolidWorks to see holographic versions of their design projects on HoloLens 2. Students were able to have a detailed and realistic experience of their designs on the Hololens 2 that they would not have been able to using computer-aided design (CAD) software alone. We learned via Stevens Institute of Technology’s news post¹ that Dr Gebre said, “We’re using this to visualize and communicate our designs. Typically, we use 3D CAD modeling software to create designs and display them on 2D screens, but it’s a completely different experience to interact with those designs as 3D holograms in front of you”.

How students used HyperSkill and HoloLens 2

Visualizing models next to physical objects²

Multiplayer visualization and interaction with shared holograms for group collaboration²

Students visualizing models in different states and verifying scale and fit. Visualizing life size holograms of designs prior to ordering components and starting fabrication of prototype²

Testimonials

- We learned via Stevens Institutes of Technology’s news post¹ that Nicolas Ipeker ’22 and his senior design team found AR beneficial in the standing electric scooter design process. According to this news post, Ipeker realized an opportunity to reduce costs and development time by using AR and was quoted as saying, “The team was able to better visualize the scale of the model and adjust the seat, wheel, and handlebar locations without any fabrication.”

- In the Stevens Institute of Technology’s news post¹ Dr Gebre was quoted as saying, “Especially with 3D printing, we can see digitally what the designs would look like in real-world environments. This is useful for verifying the designs before we use expensive materials to 3D print parts. There are typically a lot of [physical] iterations when 3D printing new designs, so we’re hoping that, by using these types of technologies, that we can cut down on the number of iterations required to produce a prototype”.

References

- “Headsets and Holograms: Extended Reality Tech Enhances Learning”, 24 Feb 2022

https://www.stevens.edu/news/headsets-and-holograms-extended-reality-tech-enhances-learning - Faculty Extended Reality (XR) Showcase April 21, 2022 Dr. Paola DiMarzio, Department of Chemistry and Chemical Biology; Dr. Biruk Gebre, Department of Mechanical Engineering; Valerie Dumova, Division of Information Technology.