Future of Manufacturing Training

Discover the transformative power of Virtual Reality (VR) in manufacturing training. Step into a world where cutting-edge technology meets unparalleled efficiency, precision, and innovation.

Case Studies

Read our recent case studies in manufacturing training

Robotic Technician Assessment

Siminsights partnered with the ARM Institute to develop a VR based robotics technician assessment. The program focuses on analyzing a potential hire’s expertise in handling the maintenance of a palletizing robot in a virtual environment.

New Hire Onboarding

An innovative high fidelity VR-based immersive, interactive and intelligent simulation-based onboarding training program was developed using the HyperSkill platform.

AR / VR Manufacturing Training

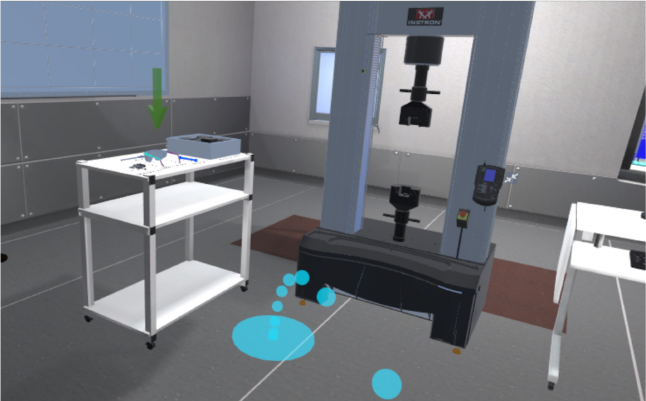

VLab is a software product for efficient creation of innovative manufacturing training content for use on a range of VR and AR devices. Specifically, VLab supports creation of equipment focused content and analytics.

Metal Additive Manufacturing

To create a system for standardizing the workflow in Metal Additive Manufacturing (AM) in order to efficiently train new operators. This project uses HyperSkill to augment manufacturing training with AR.

Enhanced Training and Safety

Immersive Manufacturing Training

Equip your workforce with immersive, hands-on training experiences. Simulate real-world scenarios without the risk, ensuring your team is prepared for any situation.

Safety Simulations

Identify and mitigate potential hazards in a controlled, virtual environment. Reduce workplace accidents and enhance overall safety protocols.

Lockout/Tagout

Train your workforce on lockout/tagout procedures in a risk-free virtual environment. Ensure they are fully prepared to handle hazardous energy sources safely.

Compliance

Use VR to deliver comprehensive OSHA compliance training. Ensure your team understands and adheres to all relevant safety regulations and standards.

Robotics Training

Use VR to train your staff on the operation and maintenance of robotic systems, ensuring optimal performance and safety.

Digital Twins

Build digital model that mirrors real-world data and behaviors, allowing users to simulate, analyze, and optimize operations in a virtual environment.

Design, Process, and Sales

Rapid Prototyping

Visualize and iterate designs in 3D. Experience the ease of making real-time modifications, reducing the time and cost associated with traditional prototyping.

Collaborative Design

Bring your teams together from across the globe in a virtual space. Share, critique, and perfect designs collaboratively, breaking down geographical barriers.

Production Planning

Use VR to map out production lines and workflows, optimizing every step of the manufacturing process for maximum efficiency.

Maintenance

Simulate machinery operations and predict maintenance needs before they become critical, reducing downtime and extending equipment lifespan.

Virtual Showrooms

Showcase your products to potential clients in an interactive, immersive environment. Highlight features and functionalities in ways that static displays can’t match.

Customer Engagement

Engage customers with virtual tours of your manufacturing processes, building trust and transparency.

Showcase

Virtual Reality-Based Robotic Technician Assessment Test

The aim of the project was to utilize VR to create and deliver an employee assessment for the maintenance of a palletizing robot. Users would be presented with a specific fault in the robot and asked to use their knowledge and experience to identify the fault, utilize the tools in the work cell environment to address or fix the issues, and return the robot to working condition at the conclusion of their procedure. The simulation was developed in collaboration with the customer and their Subject Matter Experts (SMEs).

Virtual Reality-based worker onboarding simulation

An innovative high fidelity VR-based immersive and interactive training program was developed. The program was pilot tested to evaluate ROI (650% over 3 years) and found to deliver excellent outcomes. The program was then deployed into production, and is serving as a model for other plants in other states in the US.he fact that the training was mainly done in VR simulations, away from the factory floor, allowed normal production to run without any significant interruptions. The VR training was being conducted off the production floor, which saved almost all of the $126K annually in product wastage costs attributed to the employee training. In addition, the new process was much more scalable, as reliance on the availability of expert trainers was enormously reduced. Learners could practice their tasks without hand-holding of supervision by the experienced employees.

Lockout / Tagout (Safety) Simulation Training

Simulation in which learners will be introduced to a scenario wherein they need to apply the OSHA approved Safety Procedure – Lockout / Tagout before attending to repair a malfunctioned robotic arm. This simulation will give the learners hands-on experience on learning the correct process and procedure to implement the Lockout Tagout process.

Factory Assembly Line in VR with HyperSkill – Breadboard Assembly

In this VR and web based multiplayer simulation, users need to assemble two different types of breadboard. Users would be split and the facilitator would assign tasks for each desk. In this interactable scenario, users need to assemble the breadboard with different springs.

Data Centre Training in VR with HyperSkill

In this simulation, the learner is given step by step instructions to guide them for a two person host removal. Users need to interact with various virtual equipment based on the instructions given to them. These instructions help the learner to quickly learn the different procedures in safe extraction of the host. This VR experience helps the user to train themselves in a safer environment and as many times as possible to build their confidence.

How to use a HaaS CNC lathe

This is a manufacturing based simulation, where students will be learning the steps involved in using an CNC lathe machine. The goal of the students is to follow instructions and create a chess piece from the specimen provided to them. In this simulation, learners learn the steps for machining a chess piece using a CNC Lathe machine. Hyperskill, authoring platform can be widely used in the manufacturing industry for teaching students as well as employees in procedural knowledge that is required in manufacturing industry.

5S Simulation

5S is a five step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes. It’s simple for anyone to start applying the 5S process. It may be applied globally in all business kinds, including manufacturing facilities, offices, small enterprises, major multinational corporations, and the public and private sectors, and it doesn’t require any technical analysis. It’s a fascinating tool for operators, directors, and clients alike because of its simplicity, practical usefulness, and visual nature.

Forklift Training simulation

Forklift virtual reality (VR) training is a type of training program that uses VR technology to simulate real-life forklift operation scenarios. The training program aims to provide forklift operators with a safe and immersive environment to practice and improve their skills. The VR headset is used to display the virtual environment, and the participant uses hand-held controllers to operate the forklift within the simulation. The training program can include various scenarios such as loading and unloading cargo, navigating tight spaces, and dealing with obstacles. The virtual environment can also be programmed to mimic different types of forklifts and environments, allowing for a more comprehensive training experience. Additionally, the program can also track and record the participant’s performance, which can be used for assessment and feedback. Overall, forklift virtual reality training is a cost-effective and efficient way to train forklift operators while minimizing the risk of accidents in the real-world.